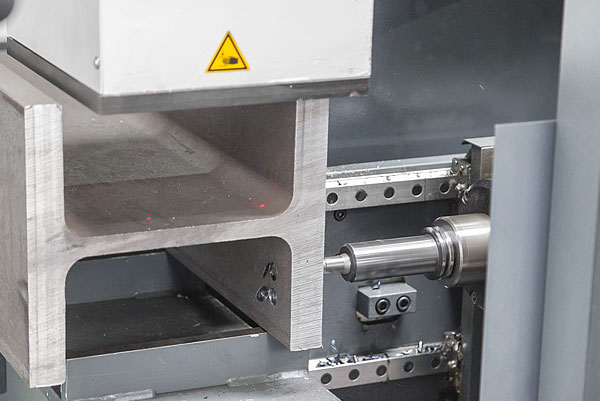

Angle

The CNC Drill Line can be operated easily and Avenger operators are the ones who lay out the floor. You don't need any prior computer knowledge and are given full training at the time of installation.

GSS Machinery's support has been invaluable in enabling us to excel in the steel fabrication market that we currently find ourselves in.