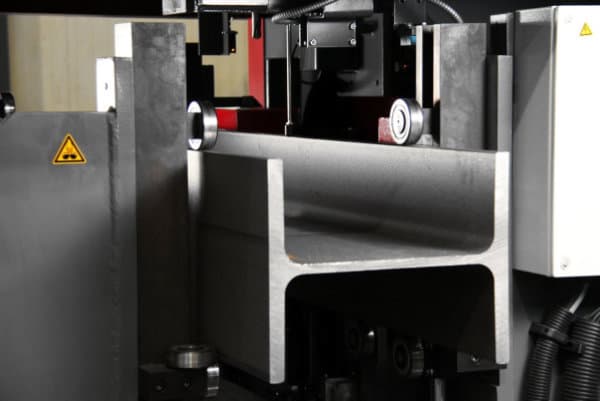

It is no good having a CNC drilling machine if it doesn�t enable a fabricator compete at the top of the steel fabrication field. Advantage-2 allows you to process technical programmes with speed and intelligence. Each drilling axis includes three five-station tool changers. Each can drill, countersink and tap as well. Signomat underside scribers or part stamping units are also possible to be fitted to this drill-line. Part information is kept even after blasting, painting and galvanizing. Minimizing shop errors? Check. Advantage-2 drills more aggressively and produces more holes than any other line of drilling. High torque drilling axes have thicker, more aggressive cuts that extract more chips with each turn. This drill line can eat through beams as well channel, angle and tube. Advantage-2 is able to process any profile up to 44 inches wide x 18 inches tall.

Auto Standoff - This is a surface standoff, and should not be confused in any way with vector standoff using 5-axis mode. Auto stand-off will adjust vertically according to the angle of "A" Axis. There are five (5) axis that are considered during calculations. The machine can be controlled manually using buttons on its screen to make the vector standoff change.