What are the four main types of drilling

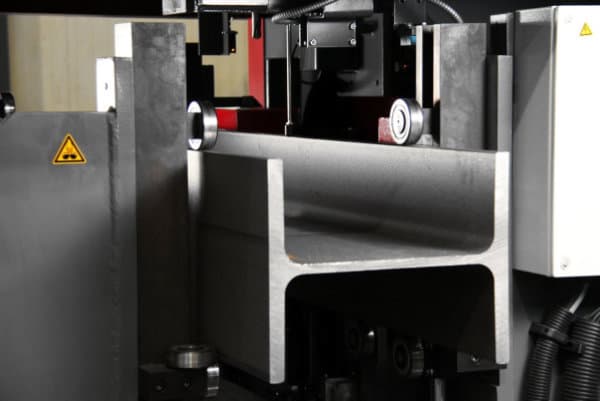

The CNC Beam Drill Line, which can be used to fabricate structural steel or miscellaneous metallics, was immediately a hit with small to medium size fabricators. Since 2003, more than 600 CNC Drill Lines were installed all over the globe. This incredible machine has transformed the lives many a steel fabricator.

�..In an effort to meet customer demands and increase production, we have installed a new beam drill line the resulting reduced labor cost and quicker turnaround times have consistently helped usin landing quality jobs.