Akyapak 3adm

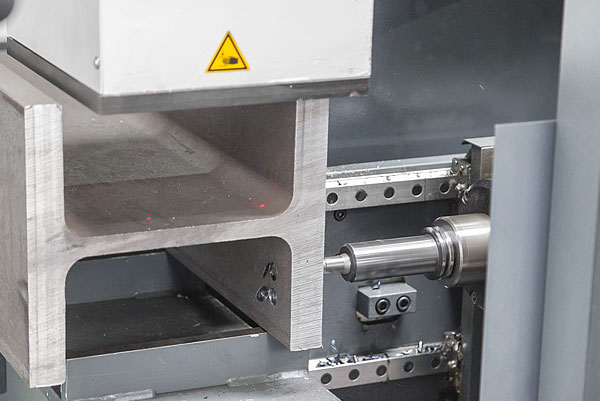

FlexBeam, a machine tool that produces steel profiles quickly and accurately, has just been launched. This machine can be used to process large jobs in small and medium-sized fab shops.

CNC Drill Line was designed for fabricators and general job shop personnel who need to drill holes in all kinds of steel profiles. These questions will help you determine if the machine is right for you.