Not every problem can be diagnosed with remote assistance. Mechanical issues or questions that require the human eye are still common. Voortman machines are shipped with high definition web cameras and software; allowing Voortman employees to directly experience the activity at the installation without the need to leave the office. The webcam has significant value in foreign countries or in situations where language might be a barrier to effectively communicate the issue.

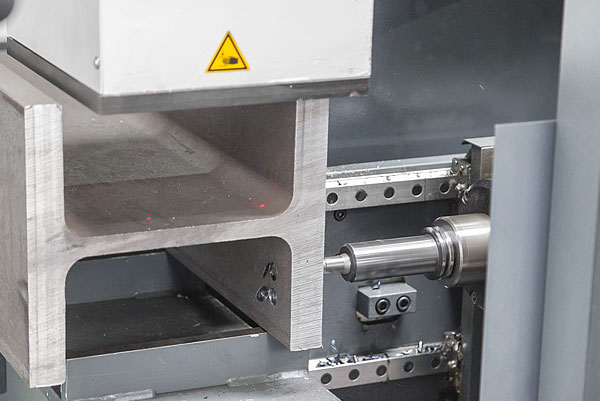

All of our beam drill lines machines are equipped with central lubrication, linear guides, and a tool cooling to ensure smooth operation. There is a four-station tool changer within each coordinate system. This allows the machine to drill and mill, scribe, countersink, or tap as required. Tools can be easily swapped mid-operation. A positive beam positioning arm is attached to the feed conveyor. It allows for more precise positioning of the beam as it moves through the drillline. The rack and pinion system maintains.004" making our steel beam drilllines more accurate than friction roll machines.