Akyapak 3

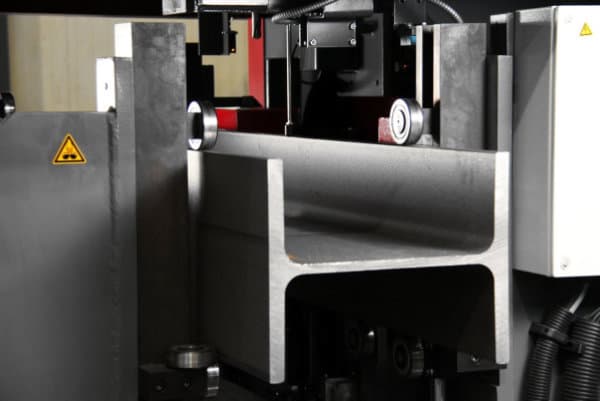

CNC Drill Line is made for fabricators and other job shops that drill holes in various types of steel profiles. You can determine if this machine meets your needs by answering the following questions.

Voortman AccuMeasure Roller Feed measurement equipment offers saw measurement options. AccuMeasure provides complete handling versatility while offering a simple, streamlined CNC solution. This allows for both a drill and saw to be disassembled, which maximizes production.